If you didn't catch last week's episode of PicklePod (which is now co-hosted by Pro Zane Navratil)...

We talked at length about inconsistencies in paddle technology, the paddle-testing process, and how the highest level of pickleball is plagued with irregularities leading to possible unfair advantages.

"But don't they have testing processes?" - You

"Yes, but they might as well not" - Me

Once Upon a Time

We'll get to Dwell Time, but first a bit of a backdrop. Once upon a time in early 2021, a brand called Electrum came along and the pickleball world collectively shi** their pants.

Electrum pushed the limits of paddle grit and pop, and soon other manufacturers followed suit. Every new paddle released was gritty this, carbon-fiber that, and pickleballers everywhere added new, and better, shots to their arsenals.

Then it was CRBN that was under the microscope, and they were even banned by USA Pickleball (USAPA) for a moment.

We were introduced to the concept of "batches." Inconsistencies in the manufacturing process (and this is pretty much universal) result in inconsistencies in the paddles themselves (i.e. variations in surface roughness, pop, weight and more).

Batches of the same paddle, despite having been produced by the same manufacturer, can differ.

Imaginary Brand, Inc. manufactures paddles. They release their new model, the Y.

The Y is manufactured in batches of 100 paddles at a time. Imaginary Brand sends 10 paddles from Batch 1 to USA Pickleball for testing and approval. The paddles pass the tests, and the Y is now USAPA approved.

The paddles in Batch 2, on the other hand, are on average grittier (more surface roughness) than those in Batch 1. Some of them would not pass USAPA's testing process. But who cares, they already got the stamp of approval...

Batch 2 paddles are sent to retailers like Pickleball Central and Fromuth (10% off equipment with code 10DINK), ambassadors, sponsored pros, etc.

And here's the thing, Imaginary Brand, Inc. doesn't even know! As far as they're concerned, they've done everything by the book.

Eventually, and understandably, the focus has shifted toward USA Pickleball, and specifically, their paddle-testing processes.

Today, the paddle-testing processes of all organizations remain in question, because there are some glaring shortcomings, which USA Pickleball has all but directly acknowledged.

And without further ado...

Dwell Time & Deflection

Introducing Dwell Time, or as some refer to it, Deflection.

Update: Yesterday while recording PicklePod (episode should be released later today) with Zane, we realized that deflection and dwell time, though closely related, are not the same thing.

First paddles were illegally having too much grit now they are illegally having too much deflection. Paddle testing needs to be implemented with not just grit, but deflection as well.

— Anna Leigh Waters (@AnnaLeighWaters) February 16, 2023

Essentially, dwell time is how long the ball dwells on the paddle face upon making contact. Deflection is how quickly the ball departs from the paddle face upon contact. In colloquial terms, deflection = 'pop'.

According to USA Pickleball's website:

The test used to measure the rigidity of a paddle is the Deflection Test. When subjected to the tests, the paddles must meet the following requirements:

- 5 thousandths of an inch or less at a test weight of 3 kg.

- 10 thousandth of an inch or less at a test weight of 5 kg.

Paddles that exceed these specifications may produce a trampoline effect and will be placed on the USA Pickleball Approved list as Fail.

Think of a tennis racquet, where the strings give and partially envelope a tennis ball upon contact. This creates a slingshot, or 'trampoline' as USAPA refers to it, effect that increases ball velocity off the face of the racquet, or paddle in our case. It also tends to add more spin and allow players to more effectively shape the ball's flight path.

But why is this suddenly in issue? Well, because everyone is talking about it.

I'm clearly not afraid to share, but I don't know enough about paddle testing to speak confidently on it. But, I do agree with AL. Deflection seems to be where companies are moving to push the limits now. Legacy Pro and Six Zero (sp?) are the ones that are next level poppy AF

— Rob Nunnery (@_robnunnery) February 17, 2023

But there's more. Dwell time influences the sound upon contact as well. And in the fractions of seconds it takes for pickleballers to react in the midst of a firefight, sound matters.

It's very quiet and soft regardless of how hard it is hit (Legacy). Talked to Simone about this in Daytona. We rely so much on sound for timing that it really messes with you.

— Rob Nunnery (@_robnunnery) February 17, 2023

This is admittedly a bit above my pay grade. Do I rely on sound? How would I know? Maybe I do subconsciously?

Can You Test It?

So how do you test deflection? Can you? According to USAPA, you can:

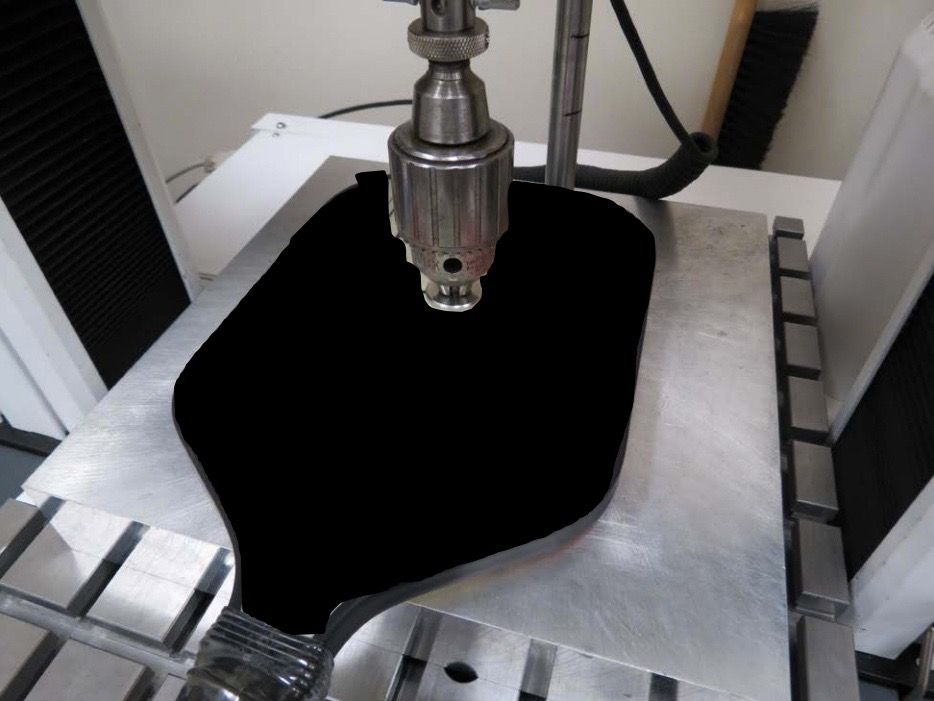

Oh perfect, sounds super easy to execute...at least you don't need a massive industrial drill-like device. Oh wait...

When USAPA tests a batch of paddles from the manufacturer, that paddle model is declared USAPA Approved. This approach has an obvious flaw. If one batch can differ from another, then the test needs to be applied to all batches, and all paddles, for that matter.

But you can't test every single paddle, that's not feasible. So, most organizations moved to sporadic testing on-site at pro events.

At PPA events, players can challenge the validity of an opponent's paddle. In the last Major League Pickleball event, they weren't testing at all, but they will be rolling out a testing process for future events. At Nationals, each player's paddles were tested ahead of play and legal paddles were administered a sticker of certification.

But none of these on-site tests measure deflection. The focus has been on surface roughness. And even testing for that is an issue because the starrett profilometer device, which tests for surface roughness aka grit (pictured above), is, as many have pointed out and even documented on video, extremely inconsistent.

Why? As one commenter on our Instagram noted, "The starrett is a bad test for surface friction. It only tests the difference in peaks and valleys. It in no way indicates coefficient of friction."

Surface Roughness Test

It's a bit complicated, but in an attempt to simplify: basically you place the starret device on the paddle face and it returns a measurement. You repeat this six times. You average the readings from the six tests. If that average reading exceeds the above measurements, the paddle fails.

The problem: the starrett is inconsistent in its measurements. Multiple videos have surfaced of the starrett returning different measurements of the same exact spot on a single paddle.

Good luck, paddle manufacturers.

But let's pretend it is consistent and reliable. The starrett test still doesn't address deflection, which is now the hot topic of debate.

Why has it become more prevalent? Because it's where paddle manufacturers see the most opportunity. It's where they can safely push the limits to improve power, spin and shape, without violating USAPA's regulations.

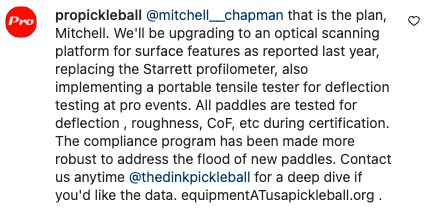

In response to the previous Instagram comment, @propickleball, who present themselves as representatives of USA Pickleball, offered:

So, we took them up on their offer and reached out. Here is what we received in response:

1) Equipment certification: to receive the "USA Pickleball Approved" seal, paddles must pass a series of tests to ensure that they are within industry standards and performance specifications: surface roughness, coefficient of friction, deflection, dimensions and gloss. The surface roughness element is getting an upgrade using an optical scanning platform with greater accuracy and repeatability.

2) In-market compliance: USA Pickleball is ramping up the compliance program to address the continued influx of paddles that have come to market in the past 18 months (910 paddles from 2021 to 2022). Well over 100 paddles that claim "raw carbon" as the surface finish are very close to the specification limits, and will be sampled for compliance in early 2023.

3) With the increasing attention on the pro player level, and with increased prize pools, event operators and pro players are asking for a paddle control function similar to the ITTF's "racket control" process used at all sanctioned events. USA Pickleball implemented a paddle testing function at the 2022 Margaritaville USA Pickleball National Championships, testing more than 150 pro player paddles for surface roughness using a higher spec instrument than is used for certification. We're proposing this same testing process to the pro tour operators, with a plan to implement the optical scanning platform as well as a deflection testing instrument to address concerns for "dwell' on paddles used in pro competition.

I think it's important to note that USA Pickleball is actively taking steps to address all of this. Every time we have reached out or written about rules and regulations, they've been forthcoming with information.

But Wait There's More

Another factor to consider is that dwell time increases, whereas surface roughness often decreases, with use. A paddle fresh off the manufacturing line is more rigid, and will return a different result, than a paddle that has been broken in.

Needless to say, it's pretty clear that testing on-site at tournaments is a necessity. It sounds like USA Pickleball is making moves to address this in the near term and encouraging the tours/leagues to do the same.

So there are 6 things to consider in my mind:

- Deflection increases pop, velocity

- Dwell time increases spin

- Dwell time alters the angle of trajectory

- Dwell/Deflection alter the sound

- Dwell/Deflection can't be conveniently and consistently tested on-site

- Dwell time increases with paddle use

And 3 questions:

- Can dwell time be a bad thing? We know that too much deflection can send a ball to the moon

- Is there a threshold of optimal dwell time? Deflection?

- Is that threshold beyond or within the current USAPA limits?

I guess we'll chalk all of this up to growing pains. But man, how many growing pains can one endure before we have to consider alternative diagnoses?

I think that's a good way to sum it up.

Final Thoughts

As someone who will take any advantage I can get (legal advantage that is, I'm not that shameless), my mind immediately goes to: ok, how do I buy a paddle with the highest dwell time possible?

Safe to say we'll be discussing more in depth on this week's episode of PicklePod. We'll also be covering it in our newsletter. It's totally free to subscribe, so do it!

![Buy & Sell Used Pickleball Paddles The Safe Way [Guide]](/content/images/size/w378h212/2025/01/THE-PICKLEBALL-SWAP-2--1-.png)

![Buy & Sell Used Pickleball Paddles The Safe Way [Guide]](/content/images/size/w768h432/2025/01/THE-PICKLEBALL-SWAP-2--1-.png)